New skills and a fast-disruptive mindset

In the aviation industry, investments in research and development are key to enabling a company to consolidate its competitive position at the highest levels.

By dedicating increasing resources to research, development, and technological innovation - as well as fostering synergies and partnerships across the aviation value chain (from propulsion technologies to collaborations with European agencies and airports) - Avio Aero delivers innovative technological solutions aimed at achieving carbon neutrality by 2050 and addressing the continuous challenges of the market.

Engineers and researchers at Avio Aero are deeply committed to applying cutting-edge technologies to develop engine modules and systems for a sustainable future, utilizing lean and efficient processes.

To further drive innovation, collaborations with the research network have been strengthened through the implementation of a network collaboration model. This model has led to the creation of European Technology Development Clusters (E-TDC), which foster new competencies and cultivate a fast, disruptive mindset that encourages thinking outside the box.

Landmark Technologies

At Avio Aero, we’re already developing our next generation of technologies to achieve greater fuel efficiency and reduced CO2 emissions. From Additive Manufacturing to Digital and Electrification for propulsion systems we are working today for the future of flight.

Additive Manufacturing

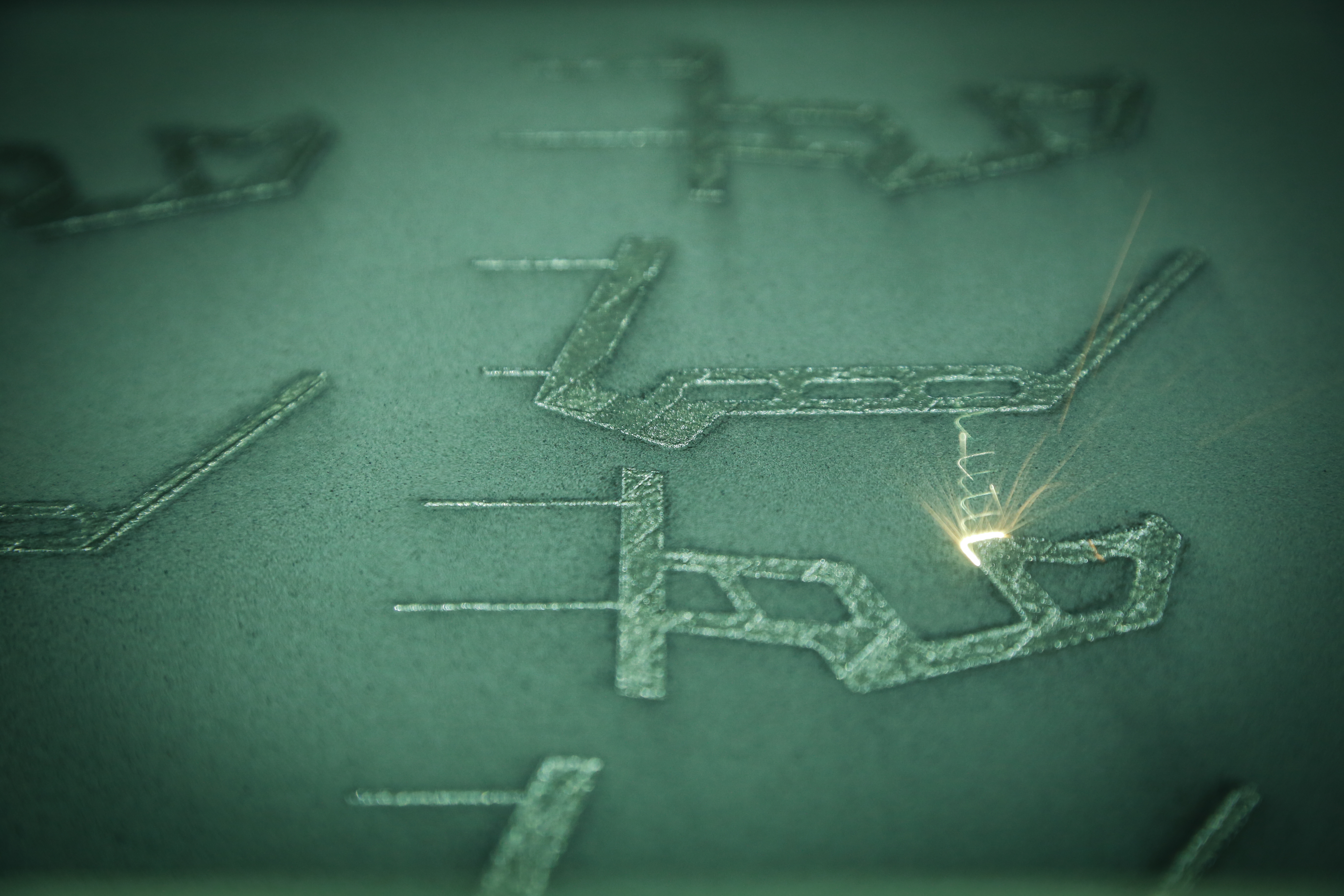

Additive manufacturing (AM) is a transformative technology that drives innovation across the aerospace industry. For Avio Aero, AM is essential to gaining a competitive edge in creating lighter, higher-performing engine systems and advancing manufacturing processes. Beyond performance, AM is a sustainable solution, offering reduced environmental impact, economic benefits, and positive societal contributions.

With more than 15 years of experience, Avio Aero has been at the forefront of designing, developing, certifying, and industrializing additive parts. Utilizing diverse processes like Electron Beam Melting (EBM), Laser, and Directed Energy Deposition (DED), our industrial sites in Cameri and Brindisi, Italy, produce certified components such as blades, heat exchangers, and combustor parts. Our lean laboratory, Turin Additive Lab, at the Turin Polytechnic campus, focuses on research and development, supported by patents, material expertise, and advanced quality systems tailored to aerospace standards.

Partnering with Colibrium, a leader in metal additive manufacturing, we leverage cutting-edge machines, powders, and consulting services like AddWorks™ to innovate further. GE Aerospace uniquely combines component production with machine and powder development, paving the way for continuous advancements in additive technology for aerospace applications.

Repair

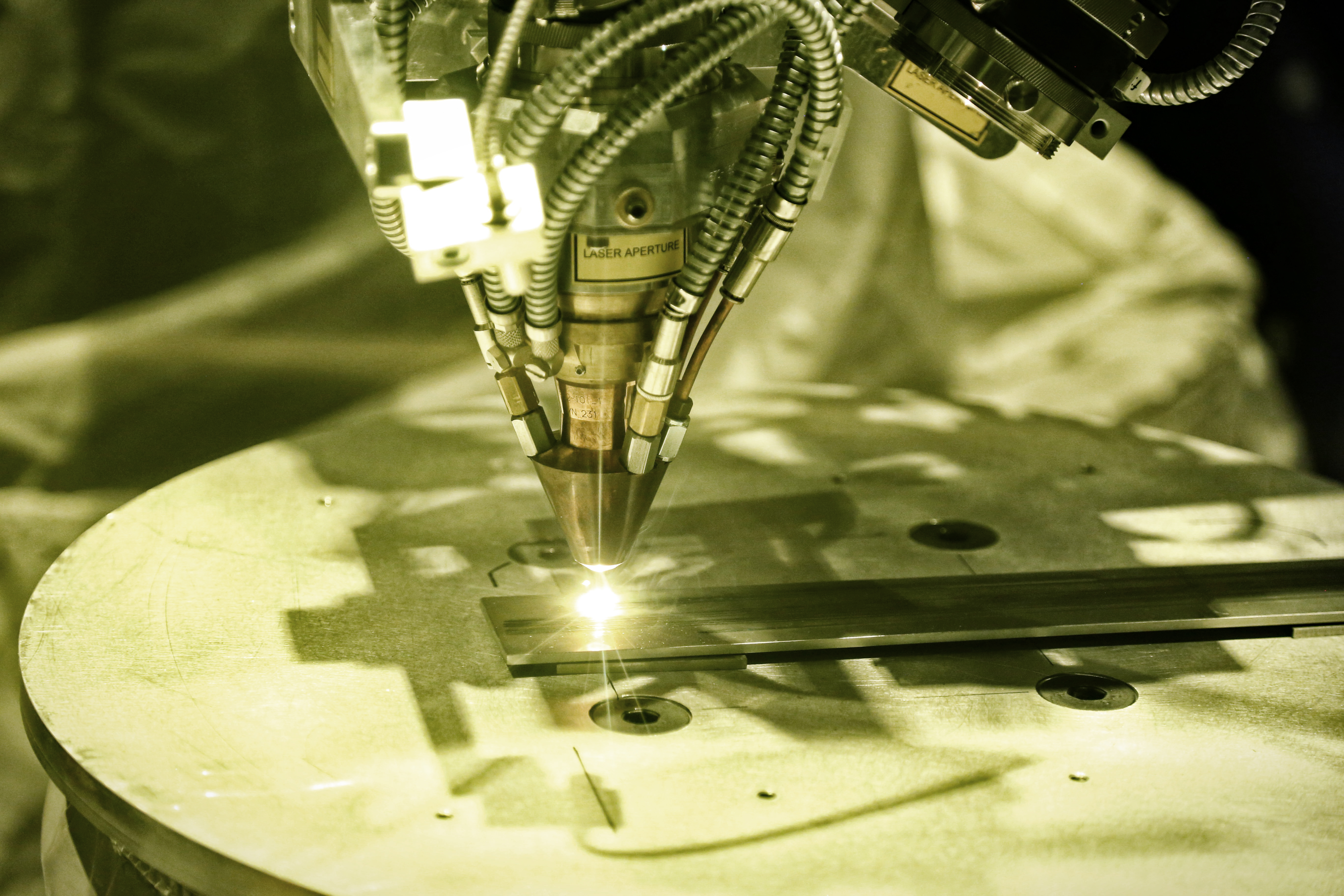

Additive repair technologies are cutting-edge methods designed to provide cost-effective solutions for repairing engine components. At the heart of this innovation is Avio Aero’s lean laboratory, the Apulia Repair Development Center (ARDC), a Center of Excellence dedicated to advancing additive repair technologies. ARDC specializes in Powder Fed Laser Metal Deposition and Cold Gas Spray techniques, enabling the repair of complex 3D geometries with near-net-shape precision and exceptional, flexibility for various materials and shapes.

The strategic mission of ARDC is to expand knowledge in distinctive repair technologies that will drive future business opportunities for Avio Aero. With strong expertise in business-driven repair solutions tailored to customer needs, these advanced repair technologies are integrated into GE Aerospace’s robust Global Sustaining Repair Engineering framework. This ensures high-quality, reliable repair processes that meet the demanding standards of the aerospace industry.

Avio Aero’s innovative repair efforts are also part of the European Technology Development Cluster (E-TDC), a collaborative network of industries and universities focused on advanced repair technologies. Leveraging decades of experience in repair process management and additive technologies, Avio Aero applies its extensive expertise to repair aeronautical components, ensuring efficiency sustainability, and excellence in every solution.

Materials

Avio Aero is at a transformative moment in its history, redefining innovation in materials and processes to meet the evolving demands of the aerospace industry. This milestone reflects the company’s steadfast commitment to progress and its ability to adapt to the challenges of modern aviation. By collaborating with a robust network of universities and agile start-ups, Avio Aero is fostering groundbreaking ideas and driving technological advancements.

The need for new platforms in commercial and civil aviation is fueling this development. As the industry seeks greater efficiency and sustainability, the demand for high-performance materials capable of withstanding extreme temperatures while optimizing fuel consumption has become critical. Avio Aero is meeting this challenge head-on, leveraging its expertise as a global leader in gearbox design and production to develop advanced steel alloys and innovative manufacturing processes. These efforts ensure components are durable, reliable, and capable of performing under the most demanding conditions.

Through its investments in cutting-edge material science and. engineering, Avio Aero is shaping the future of flight. By partnering with academic institutions, research centers, and start-ups, the company is infusing fresh perspectives into its innovation pipeline, solidifying its position at the forefront of aeronautical technology.

Technologies for combustors

At the core of every high-performance gas turbine engine is a precisely designed combustion system, and Avio Aero stands as a global leader in providing these systems for turboprop applications. Our expertise in combustion system design is centered on achieving top-tier efficiency, reliability, and reduced emissions for today’s advanced gas turbine engines. By harnessing cutting-edge technology and innovative materials, we create designs that not only meet the rigorous demands of the aerospace industry but also comply with strict environmental regulations. The Catalyst combustor exemplifies a breakthrough in combustor design, featuring a reverse-flow compact layout that integrates advanced materials, optimized geometry, and additive manufacturing techniques. This innovative approach delivers exceptional performance, setting a new standard for modern combustion systems.

Digital

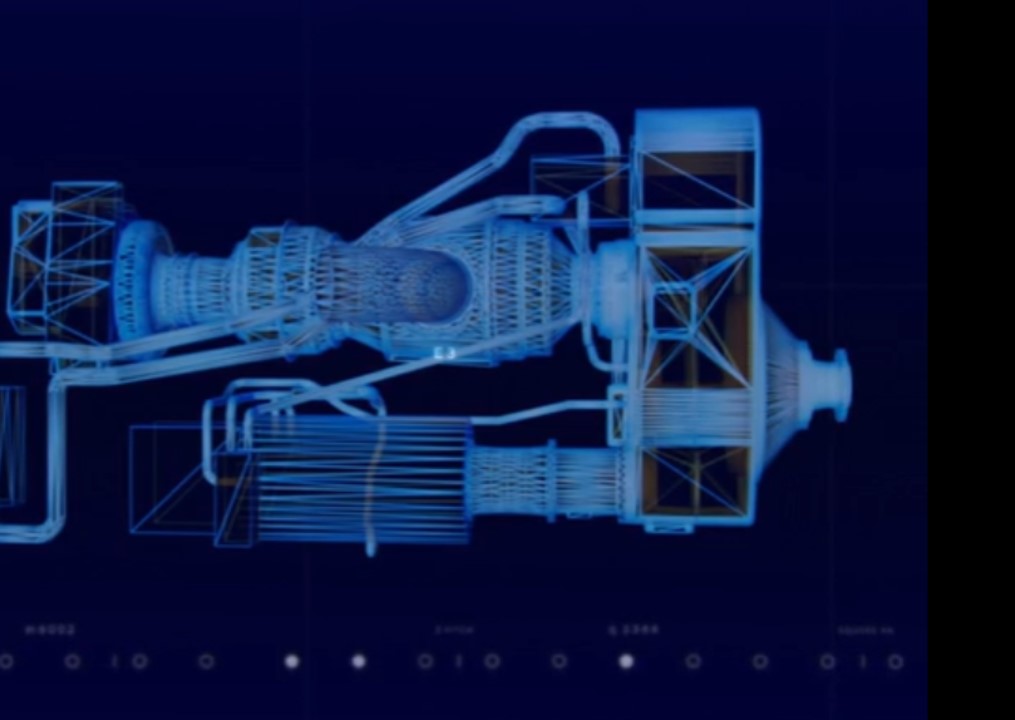

At Avio Aero, our Digital team is at the forefront of driving innovation and transformation in the aerospace industry. By leveraging cutting-edge technologies such as Artificial Intelligence (AI), High-Performance Computing (HPC), advanced analytics, and Core Enterprise Platforms that support critical business functions and workflows, we modernize workflows and create solutions that meet dynamic business needs—all while ensuring strong cyber security.

Guided by Lean and Agile principles, we work iteratively to improve processes and deliver impactful results. Collaboration is key: we partner with stakeholders to co-create digital solutions that enhance efficiency, enable data-driven insights, and foster teamwork. Our focus on safety, quality, delivery, and cost (SQDC) ensures we optimize processes for long-term success.

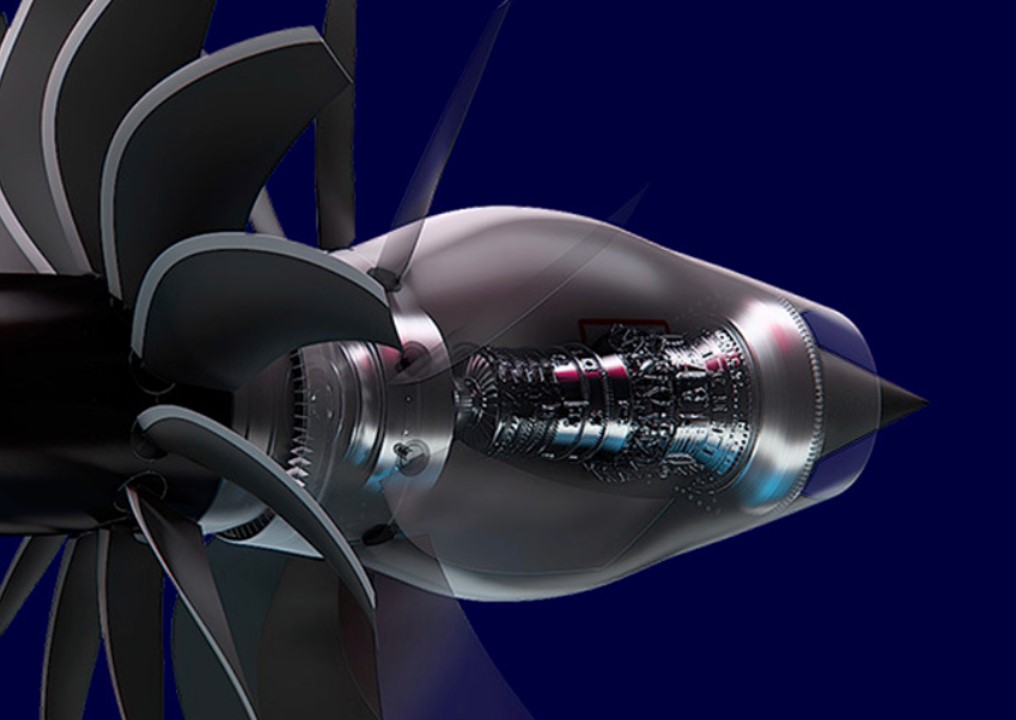

Open Fan

Avio Aero is at the forefront of innovation in aviation, playing a key role in advancing Open Fan Rotor architecture. With expertise in designing and manufacturing the Power Gearbox and High-Speed Low-Pressure Turbine, Avio Aero combines advanced aerodynamics, cutting-edge materials, and state-of-the-art engineering to create groundbreaking solutions. These technologies enable Open Fan Systems to achieve exceptional performance, efficiency, and reliability, all while reducing size and weight.

Avio Aero contributed to the development and testing of counter rotating open fan architectures under Europe’s Clean Sky research program. Under the Clean Sky 2 program, Avio Aero supported optimization of open fan architectures through design and integration studies conducted with airframers.

Electrification for propulsion systems

AMBER is a cutting-edge hybrid-electric propulsion demonstrator designed to advance technologies for a megawatt-class system powered by hydrogen fuel cells. Led by Avio Aero, the project integrates electric motors, power converters, gearboxes, thermal management systems, and supervisory controls, with module and sub-system rig tests preceding a full ground demonstration.

Building on insights from Clean Sky 2 MAESTRO and IRON, AMBER is based on Avio Aero’s Catalyst turboprop engine and aims to cut greenhouse gas emissions and fuel burn by at least 30% compared to 2020 regional aircraft standards. Recognizing regional aviation’s role in sustainability, AMBER contributes to decarbonizing aviation and reducing pollutants. Funded by Italian and German governments and Clean Aviation, the project aligns with ambitious environmental goals.

Learn more: press release

and news

Avio Aero also collaborates with NASA-GE Aerospace on the Electrified Powertrain Flight Demonstration (EPFD) project for single-aisle aircraft propulsion.

Hydrogen

Avio Aero is at the forefront of developing advanced hydrogen combustion technologies for future aviation engines.

Our innovative approach combines advanced injection systems with innovative cooling technologies, spanning from design to validation, utilizing our extensive internal and partner network testing facilities. This ensures optimal performance and efficiency while addressing future emission certification challenges.

Leveraging also additive manufacturing, we design and prototype complete combustor modules tailored for hydrogen combustion. At the same time, we focus on fuel delivery systems and engine actuation management, exploring alternatives to traditional fluid-driven systems. These breakthroughs are set to transform aviation propulsion, creating sustainable, high-performance aeronautical engines for the future. Safety, quality, and innovation are at the heart of everything we do, driving us forward in this exciting journey.